Since opening our doors in 1923, Alliance Rubber Company has established itself as a world leader in the manufacturing of custom rubber bands and other organizational tools. Our 2,200 innovative products are marketed in 60 countries, and as a third-generation family business, we’re committed to manufacturing our products in the United States and upholding the highest standards for quality, efficiency, and customer service. Our facility in Hot Springs, Arkansas, employs 165 incredible team members, more than half of whom have been with the company for more than five years.

Our wide selection of rubber products and organizational tools, including digital image wrist bands, workout bands, silicone bracelets, and more, are centered around what we’ve done best for nearly 100 years: custom rubber bands.

How Are Rubber Bands Made?

Rubber comes from plants and has been used for centuries by numerous individuals and industries. It was discovered by Europeans to erase pencil marks and proved useful for waterproofing, but the commercialization of rubber was a challenge due to its characteristics (brittle in the cold, gooey in the heat). It wasn’t until Charles Goodyear discovered the vulcanization process in 1839 that rubber was able to be stabilized and used for a variety of purposes. Just a few years later, the rubber band was invented.

Rubber comes from plants and has been used for centuries by numerous individuals and industries. It was discovered by Europeans to erase pencil marks and proved useful for waterproofing, but the commercialization of rubber was a challenge due to its characteristics (brittle in the cold, gooey in the heat). It wasn’t until Charles Goodyear discovered the vulcanization process in 1839 that rubber was able to be stabilized and used for a variety of purposes. Just a few years later, the rubber band was invented.

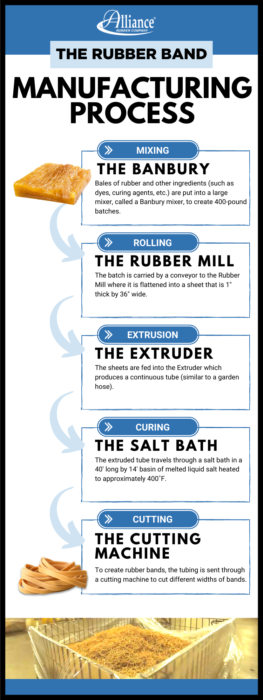

Today, rubber band manufacturing is a multi-step process. In short, it looks like this:

- The latex is harvested and purified, then mixed with acetic or formic acid to ensure the rubber particles stick together. It’s then formed into slabs and shipped to rubber manufacturers.

- The rubber is mixed with chemicals to enhance or diminish elasticity, change the color, and more.

- It’s put through the milling process, where it’s heated and pressed flat.

- The rubber is cut into strips and passed through an extrusion machine.

- After the curing process, the rubber is sliced into finished rubber bands.

Rubber bands are useful in schools, retail stores, food and beverage companies, the post office, and so many other places due to their stretchability and elasticity. Rubber bands are stretchy because of entropy, which is a state of disorder. When a rubber band is at rest, rubber molecules are tangled in a random mess, meaning they have high entropy. When you stretch it, the disordered molecules straighten, meaning they have less entropy. Once you let it go, the molecules return to their relaxed state or disorder and high entropy.

As you’ve probably experienced, they can only “bounce back” for so long. Cold temperatures make rubber bands brittle and prone to snapping. Oxygen and UV light break the rubber down over time, and eventually the band loses its elasticity—which is why outdoor rubber bands are typically made to be UV and ozone resistant to help prolong their lifespan. These EPDM rubber bands are made of heavy-duty, non-latex synthetic rubber to withstand harsh and ever-changing environmental conditions.

Services & Products by Alliance Rubber

Alliance Rubber is a trusted partner for private label manufacturing. As an ISO 9001:2015 certified lean manufacturer with extensive capabilities and years of experience, we’re prepared to handle orders of all sizes. From basic commercial rubber bands to custom printed rubber bands and produce and floral bands, our patented soft-stretch system ensures the bands are strong enough to secure your bundle while being easier to stretch. Take a closer look at our wide range of consumer and industrial rubber products.

Rubber Bands from Alliance Rubber

You’ll find rubber bands in use everywhere from the post office to the grocery store, and the option to customize these bands makes them even more useful. We can print moving supplies or food bands with your logo, address, instructions, barcodes, or QR codes to fit your specific needs.

At Alliance Rubber, we offer high-quality custom rubber bands in a wide range of sizes and colors. Our complete line of services includes custom rubber compounding and extrusions, warehousing and distribution, die cutting, specialty imprinting, research and development, and more. Learn more about becoming a distributor of Alliance Rubber products, or contact us to place your order.